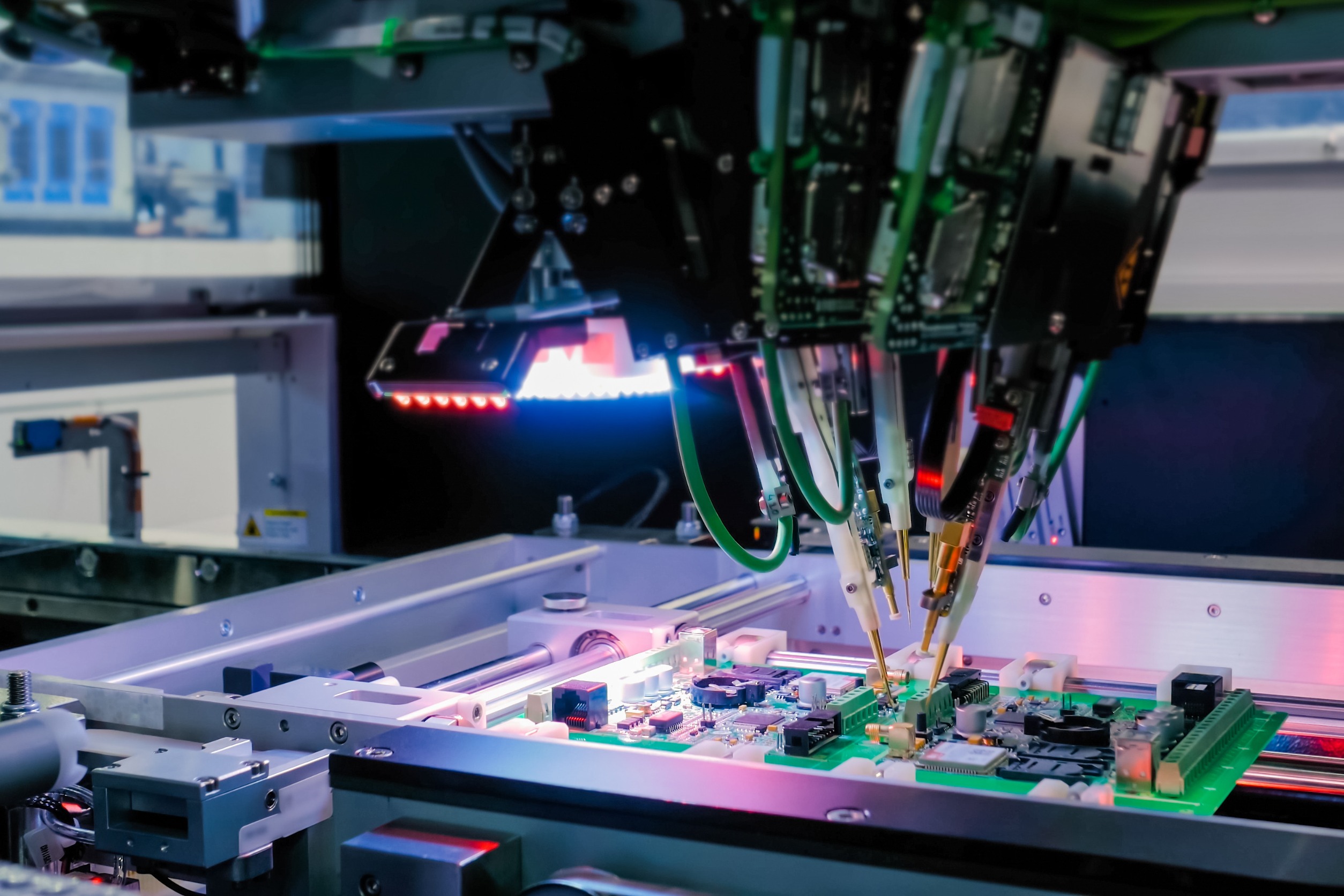

Electronic manufacturing services or EMS refers to the outsourcing of some or all of the processes involved in making electronic products. The process includes design, prototyping, production, and testing of electronic devices.

The main advantage of using an EMS is that they take care of all aspects of production, including procurement, assembly, testing, and delivery. This removes the need for the customer to have their own manufacturing resources or facilities. It also means that the manufacturer can be changed relatively easily if required. This gives them much more flexibility than if they were producing their own parts or outsourcing directly to a contract manufacturer.

Another advantage is that EMSs offer a higher level of quality control than many other types of manufacturing services provider.

Let’s discuss the factors to choose professional electronic manufacturing services

Review Quality and Reliability

Reliability and quality should be top priorities when choosing an EMS provider. Look for a partner with rigorous quality control processes and change management procedures. This ensures they can deliver consistent, high-quality products that function as intended.

The EMS provider should follow industry best practices for quality management, such as ISO 9001 or IATF 16949 certification. Ask about their quality processes, such as:

– Incoming inspection of components, devices, and raw materials

– In-process quality checks during PCB assembly and other manufacturing steps

– Automated optical inspection (AOI) to catch defects

– Functionality testing at the end of the production line

– Sample batch testing and reliability stress testing

Make sure the EMS provider has strong change management processes as well. This ensures consistent quality when engineering changes are made during the product lifecycle. They should have procedures in place for:

– Documenting and approving every engineering change

– Updating work instructions, test specs, equipment programming, etc.

– Containment when changes are made to isolate risk

– Process validation when changes are implemented

– Ongoing quality monitoring after changes

By partnering with an EMS company that adheres to disciplined quality and change control processes, you can feel confident in delivering well-made, reliable products to your customers. This should be a top priority during your selection process.

Understand Their Sustainability

When choosing an EMS partner, it’s important to consider their commitment to environmental sustainability. Look for providers that have robust environmental policies and systems in place.

Some key things to look for include:

Environmental Management System (EMS) certification – Does the provider have ISO 14001 certification or other EMS standards in place? This demonstrates a systematic approach to environmental management.

Use of renewable energy – Do they utilize solar, wind, or other renewable energy sources in their facilities? This reduces the carbon footprint.

Waste reduction and recycling – Do they have programs in place to reduce waste, reuse materials, and recycle? What percentage of waste is recycled?

Use of sustainable materials – Do they use recycled plastics, bioplastics, recyclable packaging materials, and other sustainable materials in production when possible?

Water conservation and treatment – Do they employ methods for reducing water usage and treating wastewater on-site?

Green Chemistry initiatives – Have they implemented solutions to reduce the use of hazardous substances in production?

Carbon footprint tracking – Do they measure and report on their greenhouse gas emissions and carbon footprint?

Supply chain management – Do they work with their suppliers to promote sustainable practices?

Having certifications like ISO 14001 shows structured EMS processes are in place. But also look at what concrete actions they are taking across energy, water, materials, chemicals and more. This provides a complete picture of their commitment to protecting the environment.

Evaluate Costs

When choosing an electronic manufacturing services partner, it’s critical to evaluate and compare costs between providers. The total costs go beyond just manufacturing and include expenses like components, logistics, inventory management, and more. There are a few key factors to consider when evaluating an EMS provider’s costs:

Pricing Model

Understand the provider’s pricing model – whether it’s time and materials, unit pricing, or a hybrid model. Time and materials pricing bills for labor, equipment, and materials used. Unit pricing charges a per unit fee. Hybrid models blend both approaches.

Request detailed pricing breakouts so you understand exactly what’s included in the costs. This helps avoid surprises down the road.

Compare pricing models and quotes between multiple EMS providers to get a sense of competitive rates.

Total Cost of Ownership

– Look beyond just manufacturing costs to get a full picture of the total cost of ownership with the EMS partner.

– Consider expenses like components, logistics, customs and duties, inventory carrying costs, IT systems, engineering support, testing, etc.

– Evaluate any overhead costs or markups applied by the provider.

– Discuss ways the EMS can help reduce total costs through their supply chain relationships and procurement optimization.

– Request open book pricing with full transparency into margins and markups.

Thoroughly understanding the EMS provider’s pricing model, competitiveness, and total cost of ownership helps ensure there are no major surprises post-contract. Comparing multiple bidders gives you leverage to negotiate the best possible rates too. Keeping costs low improves profitability while maintaining quality.

Choosing the Right Strategic Partner

As you evaluate potential electronic manufacturing services partners, remember that you are choosing a long-term relationship. This partnership should support your business over many product lifecycles.

Look for an EMS provider that can grow with your changing needs over time. Seek a partner that is invested in your success and provides ongoing support beyond just manufacturing services. The ideal partner acts as an extension of your team.

Consider an EMS provider that offers value-added services beyond assembly, such as design expertise, test development, global supply chain management, and aftermarket repair and refurbishment services. Their expertise and resources can complement your capabilities.

Choose an electronic manufacturing services partner that communicates openly and frequently. You need visibility into their operations, challenges, and progress to have confidence in the relationship. Make sure you can easily collaborate with their engineering, quality, and program management teams.

Evaluate an EMS provider’s financial stability. An ideal long-term partner will have the resources to continue investing in capabilities, facilities, and technology to meet future needs. Seek a partner committed to continuous improvement. Thinking long-term means choosing a strategic partner, not just a supplier. This EMS provider should share your values, vision, and commitment to quality. Taking the time to find the right strategic fit will pay dividends over the full course of your partnership.