The cost of 3D printing services can vary significantly based on the material used. This variation is due to several factors, including material availability, compatibility with specific 3D printing technologies, material properties, and post-processing requirements. In this comprehensive guide, we’ll explore how different materials impact the cost of 3D printing services.

Introduction

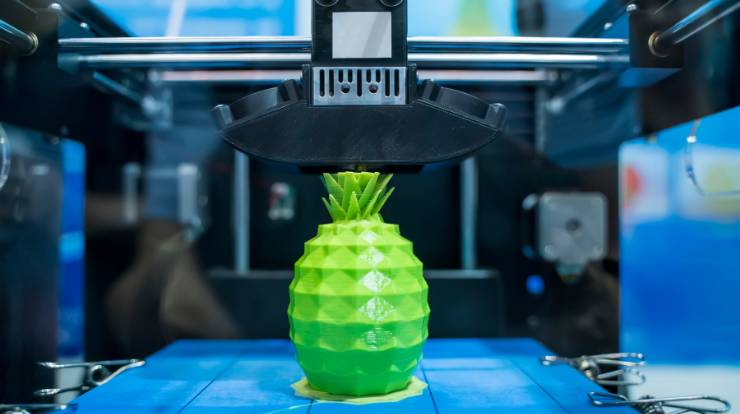

3D printing has revolutionized the manufacturing industry by offering a versatile and cost-effective way to produce prototypes, custom parts, and functional components. One of the critical decisions in the 3D printing process is selecting the right material for the job, as it directly influences both the performance and the cost of the final product.

Factors Affecting Material Costs

The cost of 3D printing materials can be influenced by several key factors:

Material Type: Different materials have varying price points. Common 3D printing materials include plastics (such as PLA, ABS, and PETG), metals (like aluminum, titanium, and stainless steel), ceramics, and even composites. Exotic or specialty materials can be significantly more expensive.

Material Form: Materials can be available in different forms, such as filaments, pellets, powders, or resins. The form affects how the material is processed and, consequently, its cost.

Quality and Purity: The quality and purity of the material can vary. High-quality, well-refined materials often command higher prices due to better print results and consistency.

Source and Supplier: Different suppliers may offer the same material at different price points. Factors like reputation, service quality, and geographic location can influence material prices.

Certifications: Materials meeting specific industry standards or certifications may be more expensive due to the rigorous testing and quality control processes involved.

Special Requirements: Some materials may require special handling, storage, or transportation, which can add to their overall cost.

Material Categories and Their Cost Implications

Let’s delve into specific material categories and their cost implications:

1. Plastics

PLA (Polylactic Acid): PLA is one of the most affordable 3D printing materials. It’s biodegradable, easy to print, and ideal for prototyping. Its low cost makes it a popular choice for beginners.

ABS (Acrylonitrile Butadiene Styrene): ABS is known for its durability and impact resistance. It’s slightly more expensive than PLA due to its mechanical properties and increased difficulty in printing.

PETG (Polyethylene Terephthalate Glycol): PETG offers a balance between PLA and ABS in terms of cost. It’s stronger than PLA and easier to print than ABS, making it a cost-effective choice for functional parts.

2. Metals

Aluminum: Aluminum is a lightweight metal that is relatively affordable compared to other metals used in 3D printing Dubai. Its cost can vary based on purity and grade.

Stainless Steel: Stainless steel is more expensive than aluminum but offers excellent corrosion resistance and strength. The cost depends on the specific alloy used.

Titanium: Titanium is a high-performance metal with an exceptional strength-to-weight ratio. It’s one of the most expensive materials due to its rarity and challenging printing process.

3. Ceramics

Alumina: Alumina ceramics are relatively affordable and widely used for their electrical insulation properties. However, advanced ceramics like zirconia can be more expensive.

4. Composites

Carbon Fiber-Reinforced Polymers: These composites are known for their high strength and low weight. They are generally more expensive than standard plastics due to the added carbon fiber.

Metal Matrix Composites: Combining metal with reinforcing materials can increase strength and thermal resistance but also raise the material cost.

5. Resins

Stereolithography (SLA) Resins: SLA resins come in various types, including standard, engineering, and specialty resins. Specialty resins designed for specific applications may come at a premium price.

Impact of Material Choice on 3D Printing Costs

The choice of material has a significant impact on the overall cost of a 3D printing project:

Material Volume: The amount of material required for a project directly affects the cost. Larger or denser parts will consume more material and, therefore, incur higher costs.

Material Waste: Some 3D printing processes generate more waste material than others. For instance, powder-based processes like Selective Laser Sintering (SLS) can have a higher material wastage compared to filament-based printing.

Machine Compatibility: Different 3D printing technologies are compatible with specific materials. The choice of technology can impact costs, as certain technologies may require more expensive equipment or specialized setups.

Print Speed: Some materials allow for faster print speeds, reducing labor and machine costs. Others may require slower printing to achieve optimal results.

Post-Processing: Material choice also affects post-processing requirements. For example, metal parts often require additional finishing steps like machining, heat treatment, or surface polishing, which can add to the overall cost.

Design Complexity: The complexity of the design can influence material costs. Intricate or detailed designs may require more material and time to print.

Case Studies: Material Cost Variations

To illustrate the impact of material choice on 3D printing costs, consider these case studies:

Case Study 1: Custom Medical Implants

Imagine a scenario where custom medical implants are needed:

PLA: PLA, being one of the most affordable materials, would be a cost-effective choice for prototyping and low-stress applications.

Titanium: For high-stress applications, titanium would be a more expensive but appropriate choice due to its biocompatibility and strength.

Case Study 2: Aerospace Components

In aerospace, lightweight yet strong materials are crucial:

Aluminum: Aluminum, being relatively affordable, might be used for non-critical components.

Carbon Fiber-Reinforced Polymers: For critical components requiring a high strength-to-weight ratio, carbon fiber-reinforced polymers might be chosen, despite their higher cost.

Conclusion

In conclusion, the cost of 3D printing services varies significantly based on the material chosen for a project. Factors such as material type, quality, source, and post-processing requirements all play a role in determining the overall cost.

It’s essential to carefully evaluate your project’s requirements and budget constraints when selecting a 3D printing material to ensure you achieve the desired balance between cost and performance. Ultimately, the right material choice can lead to cost savings, improved product quality, and successful project outcomes.